Manufacturing refers to the process of converting raw materials, components, or parts into finished goods through various production methods, techniques, and technologies. It encompasses a wide range of activities, including fabrication, assembly, machining, and quality control, aimed at creating products for consumer, commercial, or industrial use.

Manufacturing plays a pivotal role in driving economic growth, innovation, and job creation across the globe. It serves as the backbone of many economies, providing essential goods, contributing to GDP growth, and fostering technological advancements in various sectors. From automotive and electronics to healthcare and consumer goods, manufacturing impacts virtually every aspect of modern life.

Historically, manufacturing relied on labor-intensive processes, manual craftsmanship, and rudimentary tools and machinery. Craftsmen and artisans meticulously crafted products by hand, resulting in limited production capacities and longer lead times.

The advent of the Industrial Revolution in the late 18th century revolutionized manufacturing practices with the introduction of steam power, mechanization, and assembly line techniques. Mass production enabled manufacturers to produce goods on a large scale, significantly reducing costs and increasing efficiency.

In the 21st century, the manufacturing industry is undergoing a digital transformation, commonly referred to as Industry 4.0. This era is characterized by the integration of digital technologies such as automation, robotics, artificial intelligence, IoT, and cloud computing into manufacturing processes, enabling smart factories, predictive maintenance, and real-time data analytics.

Today, manufacturing spans a diverse range of sectors, including automotive, aerospace, electronics, pharmaceuticals, textiles, and food and beverage, each with its unique production processes, supply chains, and market dynamics.

Globalization has transformed the manufacturing landscape, with companies sourcing materials, components, and labor from around the world to optimize costs, access new markets, and diversify supply chains. Effective supply chain management is critical for manufacturers to ensure timely delivery, mitigate risks, and maintain competitive advantage.

With growing concerns about environmental sustainability and resource conservation, manufacturers are increasingly embracing green practices, renewable energy sources, and eco-friendly materials to minimize carbon footprints, reduce waste, and comply with environmental regulations.

The Manufacturing industry is undergoing rapid digital transformation, leveraging advanced technologies to optimize processes, improve efficiency, and drive innovation. However, along with these opportunities come a unique set of IT development challenges. In this article, we'll explore some of the key challenges faced by manufacturers in adopting and implementing IT solutions.

Many manufacturers rely on legacy systems and outdated technology infrastructure that are incompatible with modern IT solutions. Integrating these legacy systems with new technologies poses interoperability challenges and technical complexities.

Manufacturers handle sensitive data, including intellectual property, trade secrets, and customer information. Protecting this data from cybersecurity threats, data breaches, and unauthorized access is a top priority but poses significant challenges in the face of evolving cyber threats.

Manufacturers operate within complex supply chains involving multiple suppliers, vendors, and partners. Disruptions such as natural disasters, geopolitical events, and market fluctuations can impact the flow of materials, components, and finished products, posing challenges in supply chain management.

Manufacturers must be able to scale their IT infrastructure and applications to accommodate growth, expansion, and changing market demands. However, traditional IT systems may lack the scalability and flexibility required to adapt to evolving business needs.

Manufacturers must comply with various regulatory standards, industry certifications, and quality management systems to ensure product safety, environmental sustainability, and regulatory compliance. Navigating these compliance requirements can be complex and time-consuming.

In the dynamic landscape of the Manufacturing industry, staying competitive and profitable requires innovative solutions, streamlined processes, and optimized operations. Maxaix specializes in delivering tailored software solutions and services that empower manufacturers to achieve their business objectives, enhance productivity, and drive growth. Here's how Maxaix delivers business value in the Manufacturing sector.

Maxaix understands that every manufacturing business is unique, with its own set of challenges, goals, and operational requirements. That's why we offer customized software solutions tailored to the specific needs and objectives of our manufacturing clients. Whether it's improving production efficiency, optimizing supply chain management, or enhancing quality control processes, Maxaix develops bespoke solutions that address the critical pain points and opportunities within each manufacturing operation.

Maxaix's software solutions are designed to streamline manufacturing processes, automate repetitive tasks, and eliminate inefficiencies. By integrating advanced technologies such as AI, IoT, and machine learning, we enable manufacturers to optimize resource utilization, minimize downtime, and increase throughput. Our solutions empower manufacturing teams to work smarter, not harder, resulting in improved operational efficiency and cost savings.

In today's fast-paced manufacturing environment, data is king. Maxaix helps manufacturers harness the power of real-time data insights to make informed decisions and drive continuous improvement. Through our advanced analytics tools and dashboards, manufacturers gain visibility into key performance metrics, production trends, and operational KPIs. By monitoring performance in real-time and identifying areas for optimization, manufacturers can proactively address issues, capitalize on opportunities, and stay ahead of the competition.

A well-managed supply chain is essential for the success of any manufacturing operation. Maxaix provides comprehensive supply chain management solutions that help manufacturers streamline procurement, manage inventory, and optimize logistics. By improving visibility and coordination across the supply chain, our solutions enable manufacturers to reduce lead times, lower costs, and enhance collaboration with suppliers and partners.

Maintaining product quality and compliance with industry regulations is paramount in the manufacturing sector. Maxaix's quality assurance and compliance solutions help manufacturers ensure that products meet the highest standards of quality, safety, and regulatory compliance. Through automated quality control processes, real-time monitoring, and audit trails, manufacturers can mitigate risks, minimize defects, and maintain customer satisfaction.

As manufacturing businesses grow and evolve, they need software solutions that can scale with them. Maxaix's scalable and flexible solutions are designed to grow with our clients, adapting to changing business requirements, market conditions, and technology trends. Whether it's expanding production capacity, entering new markets, or diversifying product offerings, Maxaix's solutions provide the scalability and flexibility manufacturers need to succeed in a dynamic environment.

Innovation is at the heart of Maxaix's approach to delivering business value in the manufacturing industry. We continuously invest in research and development to stay at the forefront of technological advancements and industry trends. By leveraging emerging technologies such as AI, IoT, and blockchain, we help manufacturers embrace digital transformation, unlock new opportunities, and future-proof their businesses for long-term success.

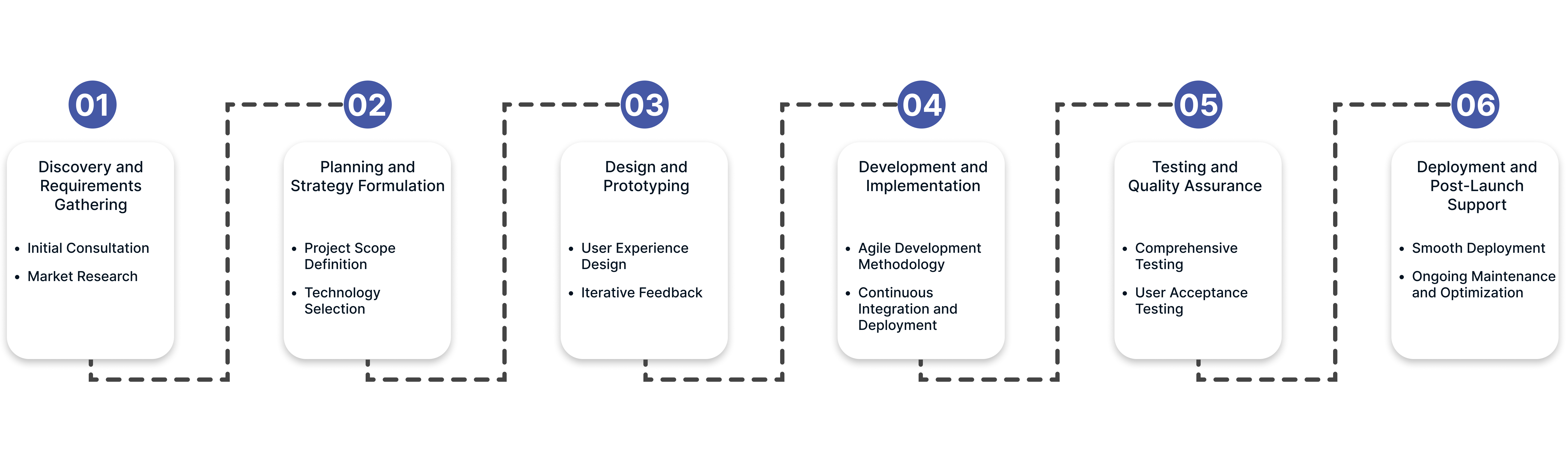

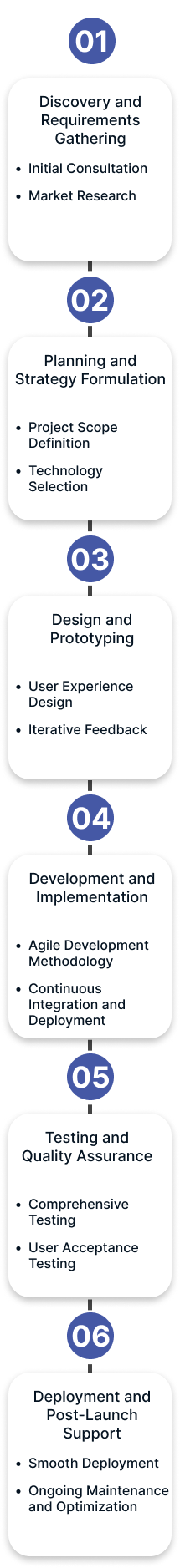

At Maxaix, we understand the unique challenges faced by the manufacturing industry and strive to deliver tailored solutions that optimize processes, enhance efficiency, and drive growth. Our development work process is designed to ensure that our clients receive innovative and effective software solutions that meet their specific needs and objectives. Here's a detailed overview of our development work process.